Introduction – From Buzzword to Board-Level Priority

Only a few years ago “artificial intelligence” felt like distant hype to most freight and logistics professionals. Today the technology is embedded in route-planning consoles, warehouse-picking arms and customs-declaration portals, turning once-reactive supply chains into data-driven, self-optimising networks. The transformation is happening everywhere, but the United Kingdom finds itself at a crossroads: international competitors are racing ahead, yet domestic adoption still hovers around one company in four. Bridging that gap will decide whether UK operators remain cost leaders in a volatile global trading system or resign themselves to playing efficiency catch-up.

This article offers a panoramic exploration of where AI already delivers measurable value, why the UK is lagging, and what concrete steps transport managers, third party logistics directors and customs specialists should take now.

From Reactive Logistics to Predictive, Self-Healing Networks

Traditional freight management has always looked in the rear-view mirror: yesterday’s delivery failures, last month’s utilisation reports, last quarter’s fuel spend. AI flips the lens forward. By ingesting live sensor feeds, real-time weather data, social-media signals and historic lane performance, machine-learning models forecast disruptions before they crystallise. A severe storm brewing over the North Atlantic? Trans-Atlantic schedules auto-adjust hours earlier, reserving scarce quay slots at an alternative port. A drivers’ strike trending on Polish news sites? UK paper merchants receive early warning, rerouting Scandinavian pulp consignments through Zeebrugge instead of Gdańsk.

The value is not simply avoiding headaches; it is unlocking time and margin. Analysts at McKinsey estimate AI-enabled route optimisation can shave 10–15 percent off fuel costs and cut delivery windows by up to two hours in dense urban corridors. For UK hauliers wrestling with tight emissions budgets and driver availability, those gains convert directly into competitive pricing and higher service reliability.

Five High-Impact Use-Cases Already Generating ROI

AI’s versatility can appear overwhelming, so focus on the handful of applications that consistently out-earn their investment.

Predictive Analytics for Disruption Management

Machine-learning engines monitor geopolitical risk, vessel positioning, road conditions and even commodity-price volatility to predict bottlenecks days in advance. Logistics planners no longer wait for the phone call that a channel port is grid-locked; they reroute the night before.

Dynamic Route Optimisation

Unlike static routing software, AI platforms recalculate paths every few minutes, weighing live traffic, toll changes and delivery priorities. Parcel integrators report up to 20 percent more stops per route and double-digit reductions in CO₂ emissions.

Predictive Maintenance

Telematics sensors stream temperature, vibration and oil-pressure readings to cloud models that flag anomalies long before breakdown. UK fleets using predictive maintenance see up to 30 percent less unplanned downtime and longer asset lifecycles.

Generative AI for Scenario Planning

When Suez Canal traffic froze in 2021, many British importers faced empty shelves. Generative AI can now simulate thousands of “what-if” trade-lane closures, proposing entirely new modal mixes or supplier bases in seconds—a job that once consumed weeks of analyst time.

Customs and Compliance Automation

AI engines inside solutions such as Customs Declarations UK’s AI Document Processing module read commercial invoices, classify goods, populate CDS fields and validate tariff codes against rule-of-origin criteria. Early adopters cut declaration drafting time by 70 percent and slash rework caused by HMRC error notices.

The UK Adoption Gap—Causes and Consequences

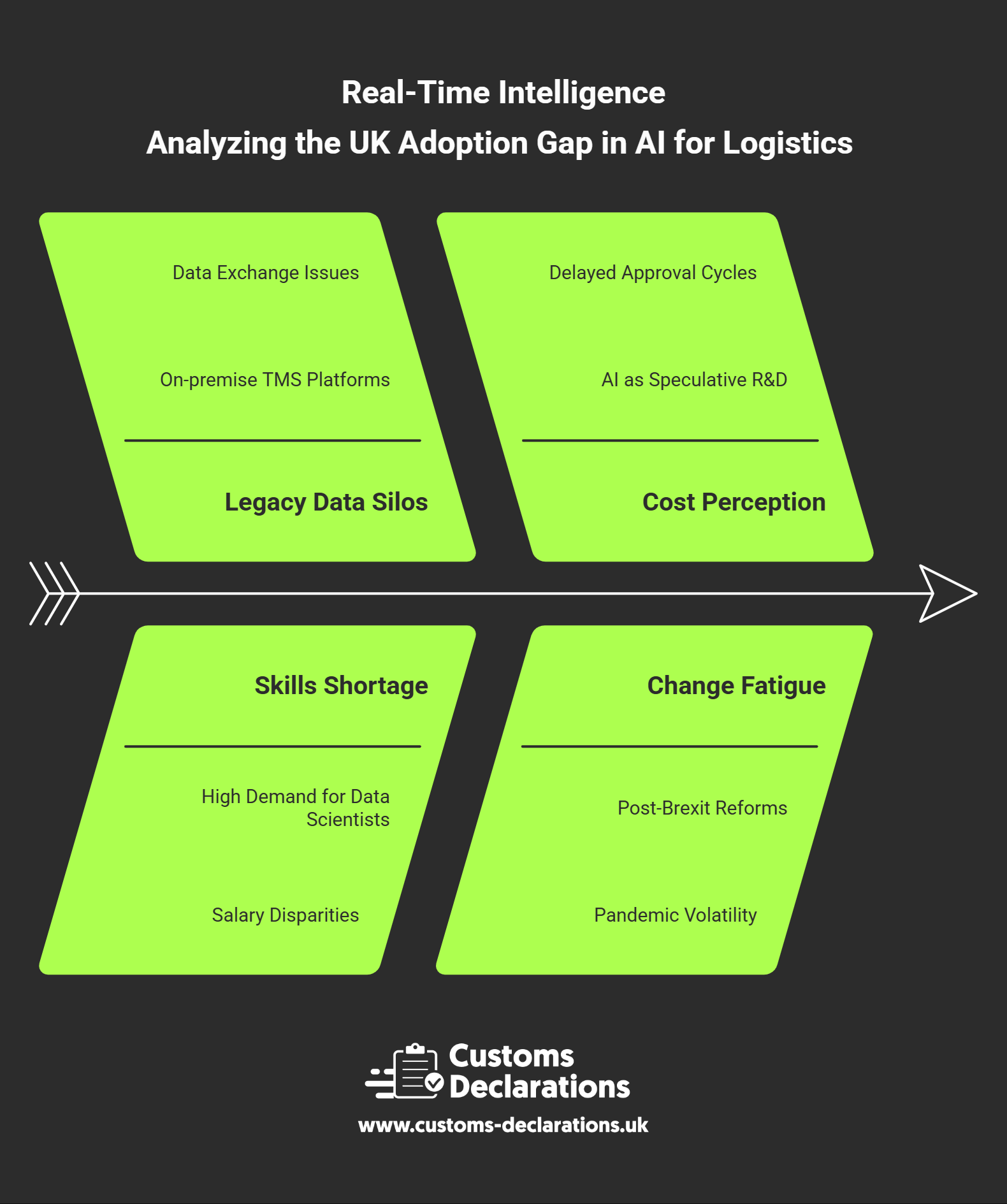

Despite these case studies, surveys by the Chartered Institute of Logistics and Transport put UK logistics AI adoption at roughly 25 percent—well below Germany, the Netherlands and the United States. Four structural barriers dominate:

- Legacy Data Silos – Seventy-percent of British freight companies still rely on on-premise TMS platforms that struggle to exchange data with cloud-native AI services.

- Skills Shortage – Demand for data scientists with logistics domain knowledge outstrips supply; SMEs cannot match fintech-level salaries.

- Cost Perception – Boardrooms view AI spend as speculative R&D rather than a bolt-on efficiency lever, delaying approval cycles.

- Change Fatigue – Post-Brexit customs reforms and pandemic volatility left teams exhausted; appetite for yet another digital overhaul is thin.

The price of inertia is rising every quarter. Global shippers now award contracts partly on supply-chain visibility and carbon intensity—metrics AI directly improves. If UK providers lag on those Key Performance Indicators, international customers will route volume through more advanced hubs in Rotterdam or Antwerp.

Overcoming Data Barriers—Building an AI-Ready Infrastructure

AI thrives on accurate, timely, richly structured data. The journey begins with a ruthless audit:

- Map Every Data Source – telematics feeds, warehouse scanners, ERP records, driver apps, customer portals.

- Consolidate via Middleware – API layers or iPaaS tools harmonise formats and expose data to AI engines.

- Clean and Enrich – resolve duplicates, standardise units, append geospatial tags.

- Govern – assign data stewards, set quality thresholds, monitor compliance with GDPR and the UK Data Protection Act.

Modern cloud integrations let even mid-sized hauliers build a scalable data lake without writing code. Platforms like Snowflake or Microsoft Fabric offer pay-as-you-go ingestion pipelines; plug-ins from telematics vendors stream sensor data automatically.

Closing the Skills Gap—People Strategy for an AI World

Technology alone cannot close the adoption chasm. Firms must cultivate “citizen data scientists”—operations managers who understand enough AI basics to collaborate with specialist teams. Actions include:

- Upskilling Programmes – sponsor courses in Python, Power BI or no-code AI tools.

- Cross-Functional Squads – pair dispatchers with data analysts on pilot projects, accelerating knowledge transfer.

- Recruitment Reboot – hire graduates with dual degrees in logistics and data science; UK universities now offer bespoke programmes.

Government grants such as the UK “Made Smarter” adoption fund can co-finance training and pilot deployments, reducing capex risk.

FAQs – Straight Answers to Real-World Questions

Will AI replace drivers or planners?

It augments them. Algorithms crunch variables faster, but human judgment still resolves ethical trade-offs, customer diplomacy and regulatory exceptions.

Is AI allowed to make customs declarations without human sign-off?

HMRC policy still requires an accountable person, but AI can draft, validate and even submit entries under a supervisor’s authorisation. The efficiency gain is in data accuracy, not legal responsibility.

Turning Compliance into Competitive Edge – AI at the Border

Post-Brexit customs complexity adds hidden hours to many supply chains. AI-powered declaration tools parse invoice line items, predict HS codes and flag licence requirements before goods leave the depot. By integrating with the CDUK “Knowledge Base”, shippers gain instant access to tariff updates, duty calculators and sanctions alerts—removing costly errors that cause HMRC holds. External benchmarks like the UK Government’s AI Action Plan for Transport outline future border-process automation, making early adoption a strategic hedge.

Future Horizons—What 2026–2030 Will Bring

- Autonomous Convoys – AI-coordinated platoons of electric HGVs could cut drag and extend range on the UK’s smart-motorway network.

- Edge AI in Warehouses – On-site micro-data-centres will process camera feeds to track pallet health, eliminating manual checks.

- AI + Blockchain for Provenance – immutable ledgers will store machine-generated audit trails, giving customs officers push-button verification of supply-chain integrity.

- Hyper-Personalised Delivery – AI will predict consumer availability windows, reducing failed first-time deliveries and city congestion.

- Green Optimisation – carbon-aware routing engines will factor grid emission intensity, steering EV fleets toward charging stations supplied by renewable energy.

Firms investing today secure first-mover advantage as these trends exit pilot phase.

Conclusion – The Imperative to Act

Artificial intelligence has crossed the line from experimental to essential in freight and supply-chain management. For UK operators, adopting AI is no longer a speculative gamble; it is the cost of staying relevant in markets where efficiency, resilience and sustainability metrics decide contract awards. The technology is ready, affordable and increasingly user-friendly. The winners will be those who treat data as strategic fuel, empower employees to wield AI tools and commit to continuous innovation. The laggards will discover that in a networked economy, every delay or empty mile echoes across their balance sheet—and their customers’ patience.

The freight revolution is real, intelligent and already rolling down Britain’s motorways. The question is whether your business plans to lead the convoy—or watch it pass by.