Introduction – From Post-Brexit Pain Point to AI-Powered Advantage

The United Kingdom’s supply-chain ecosystem has rarely faced as much pressure—or enjoyed such opportunity—as it does today. Post-Brexit rules have multiplied documentation requirements, port congestion and compliance risk. E-commerce growth has shortened delivery windows even while driver shortages squeeze capacity. Inflation and volatile fuel costs batter already-thin margins.

Into this complexity steps artificial intelligence (AI). What began as a Silicon Valley buzzword now sits at the heart of smart warehouses in Doncaster, predictive-maintenance hubs in Felixstowe and customs-automation engines that file declarations to HMRC in seconds. Far from an experimental luxury, AI is becoming the baseline capability that separates forward-looking operators from competitors doomed to constant firefighting.

This article offers a comprehensive exploration of the five highest-impact AI use-cases already delivering measurable returns for UK supply-chain stakeholders. Along the way, it answers the questions that freight planners, compliance managers and CEOs type into Google every day, and it provides practical guidance—plus strategic internal and external links—to help you embed AI where it matters most.

Predictive Analytics for Disruption Management – Seeing Tomorrow’s Bottlenecks Today

What problem does it solve?

From unexpected dockworker strikes in Antwerp to flash floods on the M25, disruptions cost UK businesses millions in missed delivery slots and emergency rerouting. Traditional risk monitoring spots trouble only after it happens; AI predicts it before it bites.

How does it work?

Machine-learning platforms ingest live feeds—geopolitical alerts, AIS vessel data, road-traffic sensors, Met Office forecasts, even trending social-media keywords. The algorithms learn patterns that historically preceded delays. When those patterns recur, the system issues early-warning signals, sometimes days in advance.

Real-world impact

Companies using predictive analytics report reaction times up to 40 per cent faster and significant savings on detention and demurrage fees. One UK retailer avoided a seven-figure stock-out bill in 2024 by diverting a critical shipment through Immingham after the model flagged looming congestion at Dover.

How accurate are AI disruption-prediction tools in logistics?

Accuracy depends on data depth and model training. Mature systems fed with multi-year datasets can achieve precision high enough that planners treat the alerts as part of daily scheduling rather than as experimental advice.

Dynamic Route Optimisation – A Sat-Nav That Never Sleeps

What problem does it solve?

Static route-planning locks a driver into yesterday’s traffic assumptions. When an accident closes the A14 or a new Low Emission Zone (LEZ) surcharge kicks in, miles of detours and cost overruns follow.

How does it work?

AI-based route engines continuously recalculate every few minutes, weighing live traffic, weather, height restrictions, toll updates, vehicle range and delivery priority. The optimal path changes organically as conditions evolve and is pushed to drivers’ onboard units in real time.

Real-world impact

Parcel integrators have squeezed up to 20 per cent more stops per route and cut fuel burn by double digits. For SMEs, pay-as-you-go cloud platforms make the technology accessible without enterprise price tags.

Will dynamic route optimisation complicate drivers’ day?

It simplifies it. Drivers receive turn-by-turn updates that shave idle time and remove manual decision-making, while fleet dashboards track compliance and eco-driving scores automatically.

Predictive Maintenance – Turning Wrenches Before the Breakdown

What problem does it solve?

Unplanned downtime for an HGV, forklift or automated sorter cascades through the supply chain, cancelling deliveries and burning overtime costs.

How does it work?

Telematics sensors stream vibration, oil pressure, temperature and brake data to AI models in the cloud. These models detect micro-anomalies—subtle shifts that human eyes miss—and forecast the remaining useful life of components.

Real-world impact

UK fleets adopting predictive maintenance have reported 30 per cent fewer roadside failures and extended asset life by one to two years. Warehouses cut emergency engineer call-outs and optimise spare-parts inventory instead of stockpiling “just in case”.

Is predictive maintenance worth the investment for small fleets?

Yes. Sensor costs have fallen sharply, and most telematics suppliers bundle basic analytics into existing subscriptions. The ROI comes from avoided tow bills, fewer missed slots and better resale value.

Generative AI for Scenario Planning – Board-Room Decisions at Machine Speed

What problem does it solve?

Traditional network-design or contingency planning takes weeks, limiting how fast firms can respond to black-swan events like the Suez Canal blockage or sudden tariff hikes.

How does it work?

Generative AI models simulate thousands of “what-if” worlds—port closures, trade-war tariffs, raw-material shocks—and score each mitigation strategy against cost, service level and carbon output. Executives see data-backed options in minutes, not months.

Real-world impact

During the 2023 Red Sea piracy upswing, a North-East automotive supplier used generative AI to model rerouting via rail and short-sea combinations. The chosen solution met customer lead-time contracts while absorbing only a three-per-cent cost increase, versus double-digit hikes for competitors who reacted later.

Can generative AI replace human supply-chain strategists?

No. It augments them. AI surfaces viable playbooks; humans vet feasibility, negotiate contracts and weigh brand implications. Think of the model as a tireless analyst, not the final decision-maker.

Customs and Compliance Automation – Filing Declarations at the Speed of Data

What problem does it solve?

Post-Brexit customs changes turned simple intra-EU shipments into paperwork puzzles. Misclassified HS codes trigger delays, fines and reputational damage.

How does it work?

AI engines read commercial documents, extract key fields and match product descriptions against historical classification databases. Rules-of-origin logic then validates eligibility for preferential tariffs, while licence checks flag controlled goods before they reach the border.

Real-world impact

Businesses using AI-driven platforms such as the Customs Declarations UK have cut drafting time by 70 per cent and slashed HMRC rejection rates. Automated validation means fewer “orange lane” inspections and faster customer deliveries.

Will AI handle all my customs formalities automatically?

AI automates data entry, document matching and compliance checks. Human oversight remains essential for complex valuation cases or licence appeals, but the manual workload falls dramatically.

Closing the Adoption Gap – Practical Steps to Make AI Pay Off

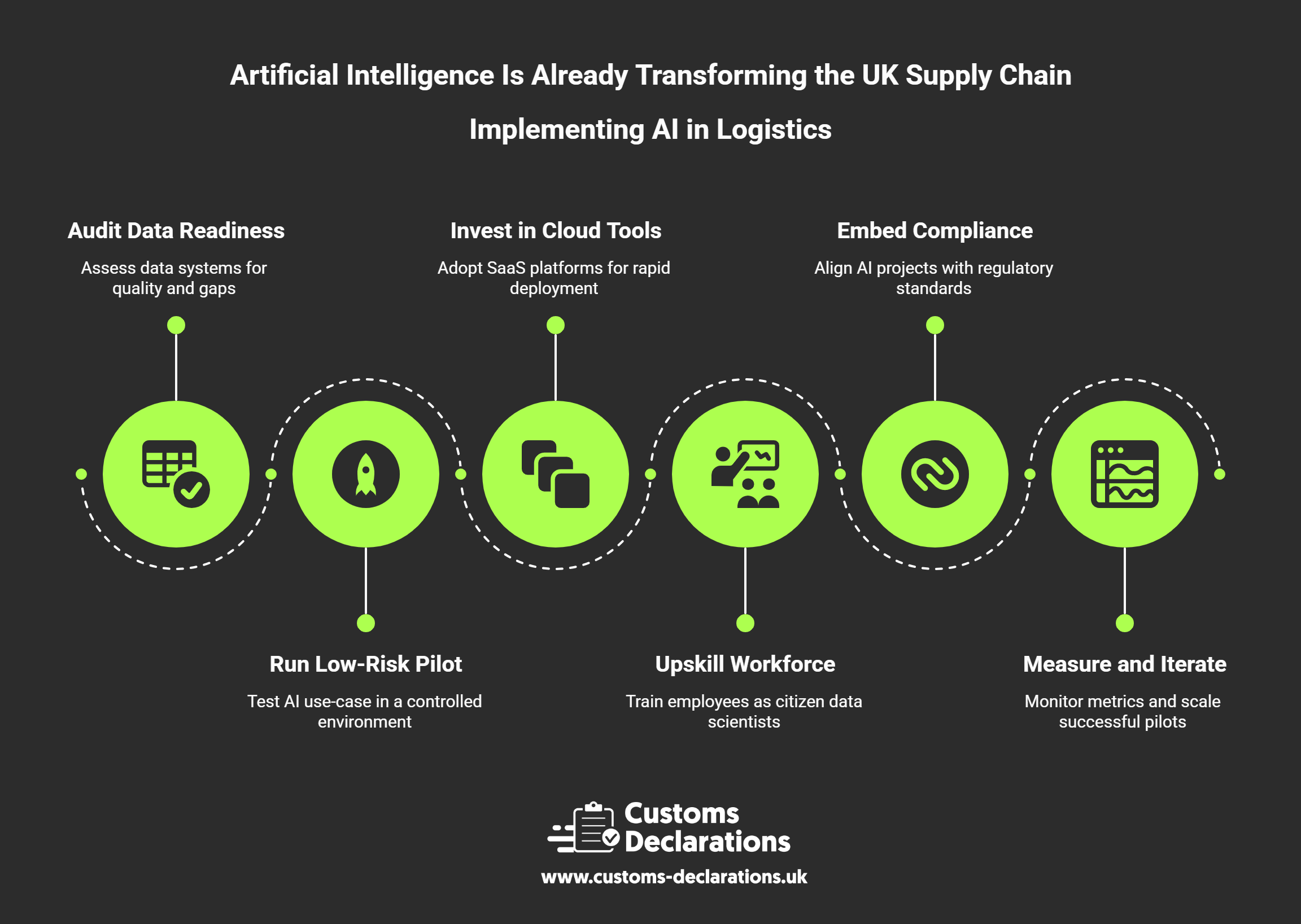

Despite clear wins, only about a quarter of UK logistics businesses have embedded AI at scale. Below is a concise action plan to move from curiosity to capability:

- Audit Your Data Readiness

Map every system—from telematics to warehouse scanners—to identify silos, quality issues and gaps. Clean data is non-negotiable for dependable AI. - Run a Low-Risk Pilot

Choose one lane, depot or asset class. Measure baseline KPIs and test a single AI use-case (e.g., dynamic routing). Quick wins build internal momentum. - Invest in Cloud-Friendly Tools

SaaS platforms offer rapid deployment and automatic updates. Integration via APIs avoids costly rip-and-replace upheaval. - Upskill Your Workforce

Train planners as “citizen data scientists” who can fine-tune algorithms, interpret dashboards and collaborate with IT on continuous improvement. - Embed Compliance Early

Align AI projects with HMRC’s digital-first roadmap. Tools that feed structured data straight into the CDUK knowledge base future-proof declarations against schema changes. - Measure and Iterate

Monitor hard metrics—fuel savings, on-time performance, clearance speed—and soft gains like customer satisfaction. Scale successful pilots across the network.

Frequently Asked, Decisively Answered

Can AI help me hit sustainability targets?

Absolutely. Route optimisation cuts CO₂ emissions, predictive maintenance prolongs asset life, and scenario planning finds lower-carbon transport modes—feeding directly into ESG reporting.

The Road Ahead – AI as Competitive Baseline, Not Differentiator

AI’s penetration of the UK supply chain is accelerating. Early adopters enjoy cost leadership and service reliability, but the technology is mainstreaming so quickly that what is advantage today will be table stakes tomorrow. Firms that delay risk watching customers migrate to partners who guarantee algorithm-optimised delivery promises, predictive lead times and frictionless customs clearance.

The encouraging news? The barrier to entry has never been lower. Cloud platforms democratise access, government grants support digital adoption, and open-source models cut development time. The decisive factor is strategy and execution: aligning AI initiatives with business goals, nurturing data culture and committing to iterative improvement.

Conclusion – Act Now, Win Tomorrow

Artificial intelligence is not a silver bullet, but it is a force multiplier. When grafted onto the UK’s complex, post-Brexit logistics landscape, AI converts volatility into visibility and paperwork into predictive insight. Whether you move five pallets a week or fifteen thousand containers a month, the tools exist, the ROI is proven and the competitive clock is ticking.

Embrace AI deliberately—start small, scale fast—and your supply chain will evolve from reactive cost centre to proactive value engine, ready for whatever the next decade of global trade delivers.